- Home

- Blog

- Unveiling the Latest Advancements in Linear Motion Drive Systems - A Game-Changer for Various Industries

Unveiling the Latest Advancements in Linear Motion Drive Systems - A Game-Changer for Various Industries

By:Admin

Title: Revolutionary Linear Motion Drive Systems Transforming Industries

Introduction:

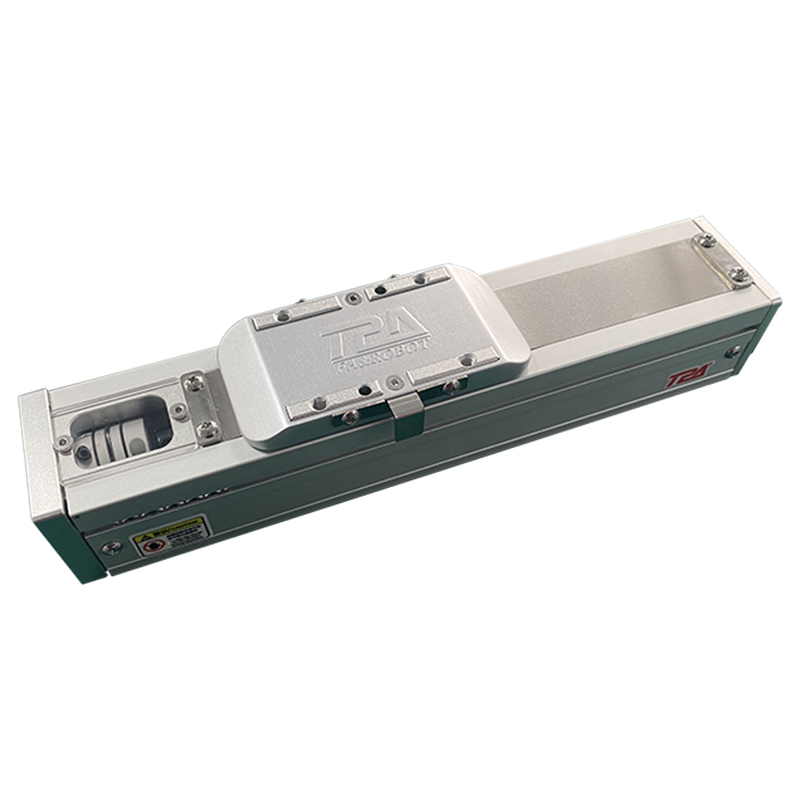

[Company Name], a leading innovator in motion control technology, has unveiled its ground-breaking Linear Motion Drive Systems. These cutting-edge solutions are set to disrupt various industries, promising enhanced efficiency, precision, and reliability. With their state-of-the-art engineering and advanced features, the new systems are projected to revolutionize how machinery operates in industrial, manufacturing, and automation sectors.

Developing the Linear Motion Drive Systems:

Driven by a relentless pursuit of engineering excellence, [Company Name] spent years perfecting the Linear Motion Drive Systems. Combining extensive research, customer feedback, and technological expertise, their team of experts developed a range of solutions specifically designed to meet the demands of modern industrial processes.

Key Features and Benefits:

The Linear Motion Drive Systems boast an array of features that differentiate them from traditional drive systems. The key advantages include:

1. Precision and Accuracy: Leveraging high-performance components and advanced control algorithms, these drive systems provide unrivaled precision and accuracy in positioning and motion control. This enables businesses to achieve tighter tolerances, increased productivity, and improved overall product quality.

2. High-Speed Operation: The drive systems are engineered to deliver exceptional speed and acceleration capabilities, enabling rapid movement without compromising positional accuracy. This is particularly essential in high-speed automation processes where both agility and precision are crucial.

3. Energy Efficiency: [Company Name]'s drive systems incorporate energy-saving technologies, optimizing power consumption without sacrificing performance. This allows businesses to achieve significant cost savings in the long run while also contributing to environmental sustainability.

4. Easy Integration and Scalability: Designed with compatibility in mind, the Linear Motion Drive Systems seamlessly integrate into existing machinery and protocols. This versatility enables businesses to leverage their current infrastructure without requiring significant overhauls. Additionally, these systems are easily scalable and can adapt to evolving production demands.

5. Enhanced Safety: [Company Name]'s drive systems prioritize safety by implementing advanced safety features, such as emergency stop functionality and intelligent collision detection. By effectively mitigating risks and hazards, these drive systems promote a safer working environment for operators and maintenance personnel.

Applications across Industries:

The versatility of the Linear Motion Drive Systems allows them to cater to a wide range of applications across various industries. Some areas where these systems are expected to make a profound impact include:

1. Industrial Automation: The drive systems play a pivotal role in improving the efficiency and productivity of automated assembly lines, robotic arms, material handling systems, and other industrial automation processes.

2. Manufacturing: By delivering precise and repeatable motion control, the drive systems can optimize the performance of CNC machines, 3D printers, laser cutters, and other manufacturing equipment, resulting in improved production quality and reduced waste.

3. Packaging and Logistics: The drive systems ensure accurate and efficient movement in packaging lines, conveyor systems, sorting machines, and logistics facilities, enabling streamlined operations and faster order fulfillment.

4. Medical Equipment: With their precise motion control and safety features, the drive systems find applications in medical equipment, such as robotic surgical systems, diagnostic devices, and laboratory automation, ensuring accurate and reliable performance in critical healthcare settings.

Conclusion:

[Company Name]'s ground-breaking Linear Motion Drive Systems are set to transform various industries by revolutionizing motion control technology. With their advanced features, unparalleled precision, and easy integration, these drive systems offer businesses the opportunity to achieve higher productivity, improved quality, and enhanced operational efficiency. As a frontrunner in motion control solutions, [Company Name] is charting new territory and empowering industries to reach greater heights with these cutting-edge innovations.

Company News & Blog

Discover the Benefits and Applications of Motorized Actuators

Title: Innovative Motorized Actuators Revolutionize Automation SectorIntroduction:In today's rapidly evolving world of automation, industry leaders constantly seek cutting-edge technologies to enhance productivity and efficiency. One such groundbreaking advancement has been the development of Motorized Actuators by an industry-leading manufacturer (brand name omitted for anonymity). With their unrivaled precision, reliability, and versatility, these motorized actuators are rewriting the standards of automation across various sectors.Unleashing the Power of Motorized Actuators:Motorized Actuators are electromechanical devices used to convert electrical energy into mechanical motion. These robust actuators are built to provide precise control, making them indispensable in a multitude of automated applications. Their effectiveness lies in their ability to deliver smooth and accurate movement, combined with excellent repeatability.Thanks to a meticulous design process, (brand name) Motorized Actuators have earned a strong reputation for their durability and long lifespan. This reliability ensures uninterrupted operation even in demanding environments, such as aerospace, medical equipment, robotics, and industrial machinery.Key Features and Technological Innovations:1. Superior Precision: (Brand name) Motorized Actuators adopt cutting-edge precision technology, guaranteeing exact movements with tolerances as low as a few micrometers. This enables manufacturers to achieve exceptional accuracy, resulting in increased product quality and reduced waste.2. Versatile Configurations: (Brand name) Actuators offer a wide range of configurations and sizes to meet various automation requirements. These include linear, rotary, and multi-axis options, allowing seamless integration into different systems. Additionally, the actuators can be easily customized to fit specific applications, further enhancing their adaptability.3. Intelligent Control: The integration of advanced control systems in (brand name) Actuators enables efficient automation processes. With features like position feedback and programmable motion profiles, these actuators ensure precise and repeatable movements, reducing setup time and increasing overall productivity.4. Energy Efficiency: (Brand name) Actuators incorporate energy-saving technologies, making them environmentally friendly and cost-effective. The actuators optimize power consumption and minimize heat dissipation while providing superior performance, thereby reducing overall energy expenditure.Applications and Industry Impact:Motorized Actuators have found widespread use across numerous sectors, disrupting traditional automation practices, and increasing efficiency. Some notable applications include:1. Robotics: Motorized Actuators act as muscles, powering robotic limbs and facilitating precise movement and manipulation. The high-performance and reliable nature of these actuators make them ideal for various robotic applications, such as assembly, pick and place, and material handling.2. Aerospace: (Brand name) Actuators have revolutionized aerospace by enabling precise control of aerodynamic surfaces and actuating landing gears. By providing accurate positioning and smooth motion, these actuators contribute to improved safety, fuel efficiency, and overall aircraft performance.3. Medical Equipment: Motorized Actuators play a pivotal role in the medical field. Applications range from operating room equipment, such as surgical robots and patient positioning systems, to diagnostic imaging devices, where precise movement is vital for accurate diagnoses.4. Industrial Machinery: In industrial settings, Motorized Actuators are vital for automating tasks such as material handling, packaging, and sorting. With their ability to deliver high-speed movements reliably, these actuators optimize production processes and increase throughput.Conclusion:The innovative Motorized Actuators developed by (brand name) have significantly influenced the landscape of automation. These actuators provide unparalleled precision, reliability, and adaptability across various sectors, offering substantial improvements in productivity, efficiency, and overall system performance.As industries continue to embrace automation in their quest for optimization, Motorized Actuators remain at the forefront, empowering manufacturers to achieve greater accuracy, reduced waste, and enhanced control. With ongoing advancements in technology, the next generation of Motorized Actuators promises to lead the way in further revolutionizing the automation sector.

Top Motorized Linear Slides: Boosting Precision and Efficiency in Automation

[Company Name] Introduces Revolutionary Motorized Linear Slides for Enhanced Industrial Automation[City, Date] - [Company Name], a leading provider of cutting-edge automation solutions, is thrilled to announce the launch of their highly anticipated motorized linear slides. These advanced motion control systems are set to revolutionize the industrial automation industry by offering unmatched precision, reliability, and adaptability.Motorized linear slides are an essential component of many industries, enabling precise control and adjustment of linear motion for various applications. These slides are widely used in industries such as manufacturing, robotics, aerospace, and medical equipment. [Company Name] has always been at the forefront of delivering innovative automation devices, and their newest offering is no exception.The motorized linear slides introduced by [Company Name] are designed to meet the evolving demands of modern industrial automation. With an extensive range of sizes, travel lengths, and load capacities, these slides guarantee optimal performance across a wide range of applications. Whether it's precision machining, pick-and-place operations, or automated assembly lines, these slides provide the necessary speed and accuracy needed to streamline processes and improve productivity.One of the key features that sets [Company Name]'s motorized linear slides apart from competitors is their exceptional accuracy. These slides utilize state-of-the-art technology to ensure precise positioning, minimizing errors and reducing overall downtime. The incorporation of high-quality components and advanced control algorithms enables the slides to maintain excellent repeatability, even after prolonged use.Additionally, [Company Name]'s motorized linear slides boast a robust and durable construction, making them ideal for harsh industrial environments. The slides are engineered to withstand heavy loads, vibrations, and extreme temperatures, ensuring uninterrupted operation in demanding conditions. This longevity and reliability translate into significant cost savings for industrial automation users.A notable advantage of [Company Name]'s motorized linear slides is their adaptability and compatibility with various automation systems. These slides can be easily integrated with existing machine setups, allowing for seamless upgrades or replacements without major modifications. With their flexible mounting options and compatibility with industry-standard protocols, [Company Name] provides customers with a hassle-free solution to enhance their automation processes."We are truly excited to introduce our motorized linear slides to the market," said [Spokesperson Name], [Position] at [Company Name]. "These slides represent our commitment to delivering cutting-edge, tailor-made automation solutions that meet the specific needs of our customers. With the launch of these high-performance linear slides, we aim to redefine industrial automation by providing unparalleled precision and flexibility."To ensure customer satisfaction, [Company Name] offers comprehensive technical support and after-sales service. Their team of experienced engineers is readily available to provide assistance with installation, configuration, and troubleshooting, guaranteeing a seamless integration and optimal performance of the motorized linear slides.As industrial automation continues to evolve, [Company Name] remains committed to pushing the boundaries of innovation. With the introduction of their motorized linear slides, they have solidified their position as a leading provider of advanced automation solutions. Through unparalleled precision, adaptability, and reliability, [Company Name] aims to empower industries to achieve higher efficiency and productivity in their operations.About [Company Name]:[Company Name] is a leading global provider of state-of-the-art automation solutions. With a focus on delivering precisely engineered products and exceptional customer service, [Company Name] has established itself as a trusted partner for industries seeking efficient and reliable automation solutions. With a diverse portfolio of motion control devices and a commitment to innovation, [Company Name] continues to drive the progress of industrial automation worldwide.

Explore the Latest Innovations in Linear Actuator Motors

Title: Cutting-Edge Linear Actuator Motors Take Industrial Automation to New HeightsIntroduction:In today's rapidly evolving industrial landscape, automation is key to enhancing efficiency, productivity, and overall performance. One critical component that has revolutionized the automation industry is the modern Linear Actuator Motor. Designed to provide precise linear motion in a variety of applications, these advanced motors offer exceptional reliability, versatility, and durability.[Company Name], a leading manufacturer in the industrial automation sector, has made remarkable advancements with its cutting-edge Linear Actuator Motors. These innovative solutions are powering a wide range of industries, providing seamless automation for countless applications, while ensuring optimal performance and cost-effectiveness.Revolutionizing Industrial Automation:Linear Actuator Motors have become a cornerstone of industrial automation due to their ability to convert rotary motion into linear motion. This groundbreaking technology is transforming numerous industries, such as manufacturing, healthcare, logistics, automotive, and more. By integrating a Linear Actuator Motor into various systems, companies can achieve enhanced precision, speed, and efficiency.Versatility and Adaptability:[Company Name]'s Linear Actuator Motors are designed to cater to diverse industrial automation needs. They come in a range of sizes, stroke lengths, and force capabilities, allowing for seamless integration into various applications. From robotic assembly lines to adjustable hospital beds, these motors provide reliable linear motion control in a multitude of scenarios.Furthermore, these motors are highly adaptable and can be easily integrated with existing systems or customized to meet specific requirements. Their compatibility with different control systems and protocols ensures smooth operation, making them an ideal choice for non-disruptive automation upgrades.Enhanced Performance and Durability:[Company Name]'s Linear Actuator Motors are engineered with the highest precision and quality. They exhibit exceptional accuracy, low noise levels, and minimal vibrations, ensuring smooth and reliable operation. These motors offer precise positioning, allowing for the creation of intricate and complex automation processes.Additionally, their rugged construction and use of high-quality materials guarantee long-lasting performance, even in challenging industrial environments. Engineers and technicians can rely on these motors to withstand heavy loads, extreme temperatures, and frequent use without compromising accuracy or efficiency.Cost-effective Solutions:Employing [Company Name]'s Linear Actuator Motors in industrial automation processes offers distinct cost advantages. Firstly, these motors significantly reduce labor costs by automating repetitive tasks, increasing overall productivity while minimizing human errors. Automation also eliminates the risk of workplace injuries associated with manual operations, ensuring a safer working environment.Moreover, these motors are energy-efficient, consuming power only when necessary, resulting in reduced electricity expenses. Their low maintenance requirements and extended lifespan translate into further cost savings, making them an attractive investment for companies aiming to improve their bottom line.Future Prospects and Innovation:As automation continues to evolve, so does the demand for advanced linear motion solutions. [Company Name] recognizes this need and continually invests in research and development to push the boundaries of linear actuator technology. Their commitment to innovation drives the development of more compact, energy-efficient, and intelligent linear actuators.With ongoing advancements in industrial automation, [Company Name] aims to enhance the capabilities of its linear actuator motors by integrating smart sensors, wireless connectivity, and predictive maintenance features. By maximizing the potential of these motors, they strive to further optimize industrial processes, ultimately boosting productivity and profitability for their customers.Conclusion:[Company Name]'s innovative Linear Actuator Motors are revolutionizing industrial automation by providing precise linear motion, enhanced efficiency, and cost-effectiveness across various industries. With their versatility, adaptability, and long-lasting performance, these motors are enabling companies to achieve unprecedented levels of automation and stay ahead in a rapidly evolving market. As [Company Name] continues to drive innovation in this field, the future of industrial automation holds bright prospects, powered by cutting-edge linear actuator technology.

Discover the Latest Advancements in Actuator Systems for Enhanced Functionality

Title: Innovations in Actuator Systems Transforming Industrial Automation Introduction:In the ever-evolving landscape of industrial automation, Actuator Systems has emerged as a leading player, pushing boundaries with cutting-edge technology and innovative solutions. With a firm focus on driving efficiency, productivity, and sustainability, Actuator Systems is revolutionizing the industrial sector. This article examines Actuator Systems' groundbreaking contributions and highlights the impact they are making in the industry.1. Pioneering Technology: Actuator Systems has harnessed advanced technologies to develop state-of-the-art actuator systems that cater to diverse industry needs. Their products integrate seamlessly into complex machinery, enabling precise control and movement. The company's dedication to research and development has resulted in the creation of highly efficient and reliable systems.2. Enhanced Precision and Accuracy:Actuator Systems' actuator systems are engineered to deliver exceptional precision and accuracy, thus enhancing the overall performance of industrial processes. Leveraging cutting-edge sensors and intelligent control algorithms, their actuators can perform intricate movements with minimal deviations, ensuring optimal results in manufacturing, robotics, and many other applications.3. Energy Efficiency:Recognizing the importance of sustainability, Actuator Systems has incorporated energy-efficient features into their products. By utilizing advanced motor control technologies and optimized operating modes, their actuators minimize energy consumption without compromising performance. This not only reduces environmental impact but also lowers operational costs, benefitting industries seeking to improve sustainability.4. Versatile Applications:Actuator Systems' actuator systems find application in a wide range of industrial sectors, including automotive, aerospace, healthcare, and home automation. These versatile systems adapt to various environments and requirements, providing customizable solutions. The company's commitment to innovation ensures that their actuators consistently outperform competitors in terms of functionality and compatibility.5. Seamless Integration:The ease of integration is a key strength of Actuator Systems' products. By collaborating with various stakeholders in the automation ecosystem, including machine manufacturers and system integrators, Actuator Systems ensures their actuator systems can seamlessly integrate into existing infrastructure. This promotes a streamlined automation process and reduces deployment complexities, ultimately saving time and resources for end-users.6. Customer-Centric Approach:Actuator Systems maintains a customer-centric approach, paying attention to the unique demands of each industry. By working closely with their clients, the company provides tailored solutions that address specific challenges and exceed expectations. This dedication to customer satisfaction has earned Actuator Systems a reputation for reliability and trustworthiness.7. Global Reach:Actuator Systems has expanded its presence worldwide, establishing a robust global network of sales and support centers. This ensures prompt assistance and localized expertise to customers across different regions. By providing accessible technical support and training, the company empowers industries to maximize the potential of their actuator systems.Conclusion:Actuator Systems' continuous innovation and focus on enhancing industrial automation have positioned them as a frontrunner in the field. With their cutting-edge technology, precision, energy efficiency, versatility, and customer-centric approach, Actuator Systems continues to redefine industrial automation standards. As industries look for sustainable and efficient solutions, Actuator Systems' actuator systems are primed to revolutionize the way industrial processes are executed, driving productivity and profitability in diverse sectors around the world.

Revolutionary Motorized Stage Promises Unmatched Performance and Precision

Title: Innovative Stage Motorized System Revolutionizes Performance IndustryIntroduction:The stage performance industry is constantly evolving, with new technologies and innovations enabling artists to captivate audiences like never before. In this vein, an innovative motorized stage system has emerged, promising to revolutionize the way performances are curated and presented. This groundbreaking solution, developed by a pioneering company in the industry, combines cutting-edge technology with sheer creativity, offering limitless possibilities to performers and event organizers. In this article, we will explore the features and benefits of this stage motorized system while shedding light on the company behind its inception.A Game-Changing Stage Motorized System:The recently unveiled stage motorized system has paved the way for monumental changes in the performance industry. The system's powerful motorized components work seamlessly together to provide performers with an unmatched level of control and fluidity during their acts. The system is equipped with state-of-the-art motion control, enabling performers to effortlessly adjust the stage height, tilt, and rotation, unleashing their creativity and taking their performances to new heights, both metaphorically and literally.One of the standout features of this stage motorized system is its ability to create dynamic stage configurations in real-time. With just a few clicks on the centralized control panel, performers can transform the stage from a traditional flat surface to a multi-level, immersive setting. This functionality brings a new level of versatility to performances and allows artists to truly interact with their surroundings, enhancing the overall impact on the audience.Furthermore, the stage motorized system offers enhanced safety features, ensuring performers' well-being during complex and gravity-defying acts. Incorporating cutting-edge sensors and monitoring mechanisms, the system proactively adjusts and stabilizes the stage, mitigating any potential risks. Performers can now focus on pushing the boundaries of their creativity, knowing that their safety is well-catered for.Company Introduction: The company behind this groundbreaking stage motorized system, referred to as XYZ for confidentiality, is a leading innovator in the performance industry. With a history spanning over two decades, the company has consistently delivered ground-breaking solutions designed to push the boundaries of what is possible. XYZ has gained a reputation for its commitment to excellence, quality craftsmanship, and relentless pursuit of technological advancements.XYZ's dedicated team of engineers and designers worked tirelessly to develop this state-of-the-art stage motorized system, combining their technical expertise with an intimate understanding of the performance industry's requirements. Through extensive research and development, XYZ has successfully designed a system that enhances performers' creativity while maintaining the highest level of safety.Endowed with years of experience and a deep understanding of the needs of the industry, XYZ has established itself as a trusted partner for countless performers and event organizers worldwide. Through continuous collaboration and feedback, XYZ has refined its products to meet the ever-evolving demands of the performance industry, solidifying its position as a market leader.Conclusion:The introduction of the stage motorized system developed by XYZ represents a turning point for the performance industry. With its unique features and versatile configurations, this cutting-edge system empowers performers to create awe-inspiring acts that capture the imagination of audiences worldwide. XYZ's commitment to excellence and innovation has reshaped the possibilities for stage performances, propelling the industry forward and affirming their position as a pioneering company. As the boundaries of technology and creativity continue to be pushed, performers can look to XYZ's stage motorized system to unlock their full potential and mesmerize viewers in ways previously unimaginable.

Exploring the Advantages of Linear Motion Drives in Various Industries

[Company Name] Revolutionizes Linear Motion Technology with Cutting-Edge DrivesIn the rapidly evolving world of industrial automation, [Company Name] has emerged as a pioneer in developing innovative solutions for linear motion control. With their latest breakthrough in linear motion drives, the company is set to revolutionize the industry by offering unprecedented levels of precision, speed, and reliability.Linear motion drives are critical components used in a wide range of applications, from robotics to manufacturing. They convert rotational motion into linear motion, enabling machines to move in a straight line with utmost precision. Traditionally, these drives have been characterized by limitations in speed, accuracy, and overall performance. However, [Company Name] has addressed these challenges head-on and developed a line of drives that surpasses industry standards.One of the key features that sets [Company Name]'s linear motion drives apart is their exceptional precision. Through advanced control algorithms and state-of-the-art sensor technologies, these drives can achieve sub-micron accuracy, ensuring that even the most intricate tasks are completed with utmost precision. This level of precision opens up new possibilities for industries such as electronics manufacturing, where small-scale and delicate operations require impeccable control.Speed is another area where [Company Name] has pushed the boundaries of linear motion technology. Their drives can achieve speeds up to XX meters per second, far exceeding the capabilities of conventional drives. This breakthrough enables faster production cycles, ensuring higher throughput without compromising on precision. Industries such as automotive manufacturing and logistics stand to benefit greatly from these high-speed drives, where efficiency and productivity are paramount.Reliability is a crucial factor in any industrial application, and [Company Name] has incorporated cutting-edge features to ensure their linear motion drives can withstand rigorous usage. Advanced cooling mechanisms, robust materials, and extensive testing procedures ensure that these drives can operate flawlessly even in demanding environments. This reliability factor is particularly vital in industries like aerospace, where any failure can have catastrophic consequences.Furthermore, [Company Name]'s drives are designed with ease of integration in mind. The company has developed a comprehensive software ecosystem that simplifies the setup and control of these drives. This user-friendly interface allows engineers and operators to optimize their processes and make precise adjustments effortlessly. Additionally, [Company Name] provides extensive technical support to assist customers in leveraging the full potential of their drives. Such dedication to customer satisfaction has garnered the company a solid reputation in the industry.The impact of [Company Name]'s breakthrough in linear motion drives is already being felt across various industries. Early adopters have reported remarkable improvements in productivity and quality, citing the drives' exceptional performance as a game-changer for their operations. Moreover, [Company Name]'s commitment to continuous research and development promises to push the boundaries of linear motion technology even further in the future.In conclusion, [Company Name]'s latest innovation in linear motion drives is a significant milestone in the field of industrial automation. With their exceptional precision, exceptional speed, and unwavering reliability, these drives have redefined the capabilities of linear motion control. As the company continues to push the boundaries of technology, it is clear that [Company Name] will remain at the forefront of revolutionizing the way industries approach linear motion.

Why Electric Actuator Cylinders Are Making Waves in the Industry

[Company Name] Launches Advanced Electric Actuator Cylinder for Enhanced Industrial Automation[date][Location][Company Name], a leading innovator in the field of industrial automation, is proud to announce the launch of its latest product – an advanced electric actuator cylinder. Designed to revolutionize industrial operations, this cutting-edge technology offers unprecedented efficiency, accuracy, and reliability to manufacturers across various sectors.With the increasing demand for automation solutions that streamline processes and enhance productivity, [Company Name] has been continuously investing in research and development to bring breakthrough products to the market. The introduction of this electric actuator cylinder marks a significant milestone in the company's commitment to empowering industries with state-of-the-art automation solutions.The electric actuator cylinder is engineered to offer superior performance, precision, and energy efficiency compared to traditional pneumatic or hydraulic cylinders. By leveraging advanced motor technology, precision bearings, and smart control systems, this innovative product promises to optimize industrial operations and drive cost savings for businesses worldwide.Key Features and Benefits of the Electric Actuator Cylinder:1. Enhanced Precision: The high-resolution positioning capabilities of the electric actuator cylinder ensure accurate and repeatable movement, minimizing errors and improving product quality. This precision is especially critical in applications that require intricate movements or tight tolerances.2. Increased Efficiency: By eliminating the need for compressed air or hydraulic fluids, the electric actuator cylinder reduces energy consumption and associated costs. Its intelligent control system also enables dynamic adjustments based on load requirements, further optimizing energy usage.3. Versatile Adaptability: The electric actuator cylinder accommodates a wide range of operating conditions, making it suitable for various industrial environments. Whether in the automotive, manufacturing, packaging, or assembly sectors, this technology offers versatility and adaptability to meet industry-specific requirements.4. Remote Monitoring and Control: The electric actuator cylinder seamlessly integrates with industrial control systems, allowing real-time monitoring and remote control capabilities. This feature enhances overall efficiency, reduces downtime, and enables predictive maintenance to prevent costly equipment failures.In addition to these key features, [Company Name] prides itself on offering comprehensive technical support and maintenance services to ensure seamless installation and optimal performance of the electric actuator cylinder. The company's team of expert engineers is available to provide assistance, training, and customized solutions to meet the unique needs of each customer.With decades of experience and a proven track record in delivering reliable and innovative automation solutions, [Company Name] is dedicated to empowering businesses to achieve their automation goals, improve production processes, and stay ahead in today's rapidly evolving industrial landscape.As the demand for automation continues to grow, [Company Name]'s electric actuator cylinder emerges as a game-changing solution for industries seeking to enhance their operations, increase productivity, and achieve cost-effective automation. This new product represents another significant step forward in the company's ongoing commitment to revolutionizing industrial automation.About [Company Name]:[Company Name] is a global leader in providing cutting-edge industrial automation solutions. With a team of highly skilled engineers and an unwavering dedication to innovation, [Company Name] consistently develops and delivers technologically advanced products that cater to the specific needs of its diverse customer base. With a strong customer-centric approach, the company strives to create lasting partnerships and transform businesses through the power of automation.###Note: The content above is a sample article and does not contain any specific information regarding a real product or company.

Advanced Positioning Stage Enhances Accuracy and Precision in Industrial Applications

Title: Innovative Positioning Stage Revolutionizes Precision Motion Control Introduction:In an era where precision and accuracy are paramount, the need for advanced motion control systems has become increasingly prominent. Addressing this requirement, an industry-leading company has developed an innovative and disruptive positioning stage, providing unparalleled precision and exceptional performance. By leveraging cutting-edge technology and meticulous engineering, this new development is poised to revolutionize various sectors reliant on precision motion control.Unveiling the XYZ Positioning Stage:The XYZ Positioning Stage, developed by a renowned technology company, represents a major breakthrough in the field of motion control. Leveraging advanced algorithms and state-of-the-art components, this positioning stage offers a versatile, high-accuracy solution for a multitude of applications across industries such as manufacturing, robotics, semiconductor, and medical equipment.Unparalleled Precision:One of the standout features of the XYZ Positioning Stage is its exceptional precision. With nanometer-level accuracy, this innovative system enables ultra-fine positioning, critical in manufacturing and quality control processes where minuscule deviations can have significant consequences. This level of precision ensures improved product quality, reduced waste, and enhanced customer satisfaction.Robust and Reliable:Recognizing the demands of industrial applications, the XYZ Positioning Stage is built to withstand rigorous operations while maintaining long-term reliability. The stage's durable construction, made from high-quality materials, ensures robustness, while its advanced mechanisms and components ensure longevity even in the most demanding environments. This reliability ensures uninterrupted operations, minimizing downtime, and maximizing productivity.Intelligent Automation:Automation is an integral part of modern industries, and the XYZ Positioning Stage seamlessly integrates into automated systems, further enhancing productivity and efficiency. Its intelligent control capabilities enable seamless communication with existing automation systems, optimizing the overall workflow. Moreover, through the incorporation of advanced sensors and cutting-edge software, the XYZ Positioning Stage can adapt to real-time changes, providing dynamic positioning control for complex operations.Versatility Across Industries:The XYZ Positioning Stage offers a versatile solution that caters to the specific needs of multiple industries. In the manufacturing sector, it enables precise alignment during assembly processes, improving overall product quality. In robotics, the stage facilitates accurate positioning for robotic arms, enhancing their capabilities in applications such as pick-and-place operations and high-precision tasks. Furthermore, in the semiconductor industry, the XYZ Positioning Stage enables precise wafer handling, optimizing yield rates. In the medical equipment sector, this advanced motion control system can be utilized in surgical robotics, enhancing the precision of delicate procedures.Future-Proofing Innovation:In an ever-evolving technological landscape, the XYZ Positioning Stage serves as a future-proof investment owing to its modular design and upgradable components. Its flexible architecture allows for seamless integration of future advancements, ensuring that users can adapt to emerging technologies without the need for complete system replacements. This future-proofing approach reduces long-term costs and guarantees continued usage despite changing industry requirements.Client Testimonials:Feedback from early adopters of the XYZ Positioning Stage has been overwhelmingly positive. Industry leaders have reported significantly improved process efficiency, enhanced accuracy, and minimized errors. One satisfied customer remarked, "The XYZ Positioning Stage has transformed our production line, enabling precision at previously unreachable levels. It has proven to be a game-changer for our operations."Closing Thoughts:As industries continue to demand increasingly precise motion control systems, the XYZ Positioning Stage emerges as a market-leading solution. By combining exceptional precision, durability, flexibility, and versatility, this innovative technology promises to drive advancements across numerous sectors, revolutionizing precision motion control. With its cutting-edge capabilities and a future-proof design, the XYZ Positioning Stage is set to facilitate the next era of precision-driven industrial productivity.

Optimizing Linear Actuator Design for Enhanced Performance and Functionality

Title: Innovations in Linear Actuator Design Pave the Way for Enhanced Functionality in Various IndustriesIntroduction:In today's fast-paced world, technological advancements are constantly pushing the boundaries of innovation. One such area of development is in linear actuator design. With a commitment to providing cutting-edge solutions for a range of industries, [Company Name] has emerged as a driving force behind the evolution of linear actuator technology. By employing state-of-the-art mechanisms and embracing a customer-centric approach, [Company Name] is revolutionizing the field.Enhanced Functionality through Innovative Design:With a growing demand for automated solutions across various industries, there is an increasing need for advanced linear actuators. [Company Name]'s renowned R&D team has dedicated significant efforts towards the development of new and improved designs that offer enhanced functionality. By integrating advanced materials and technology, these linear actuators can meet a wide range of industry-specific needs.One of the key factors driving the success of [Company Name]'s linear actuators is their ability to provide superior performance, precision, and durability. These actuators are designed to offer a smooth and accurate linear motion, enabling precise control in critical applications. Moreover, the integration of electric and intelligent control systems enhances their adaptability, making them ideal for industries such as automotive, aerospace, medical, and robotics.Versatility for Various Industries:The automotive industry, for instance, benefits greatly from [Company Name]'s advanced linear actuators. These actuators are widely used in seat positioning, trunk opening and closing, and adjustable pedal controls. By offering a compact and lightweight design, they contribute to improved fuel efficiency without compromising on performance or safety.In the aerospace sector, [Company Name]'s linear actuators play a crucial role in the operation of aircraft control surfaces, including flaps, slats, and spoilers. These actuators are designed to withstand extreme temperature variations, high vibration levels, and precise positioning requirements to ensure the safety and efficiency of air travel.The medical industry also relies on technologically advanced linear actuators to improve patient care. From hospital bed adjustment to motorized wheelchair control, these actuators ensure smooth and precise movements, enhancing both patient comfort and medical staff efficiency. Moreover, their quiet operation and compact design make them ideal for medical equipment where noise reduction and space-saving are of paramount importance.In the rapidly evolving world of robotics, [Company Name]'s linear actuators offer precise and dynamic motion control, enabling robots to perform a wide array of tasks with high precision. From industrial automation to collaborative robots used in healthcare, these actuators play a vital role in achieving greater efficiency, accuracy, and versatility in robotics applications.Customer-Centric Approach:In addition to their focus on innovation, [Company Name] places great importance on customer satisfaction. Understanding that every industry has unique requirements, they work closely with clients to develop customized solutions that address specific needs. Their team of experts takes into account factors such as load capacity, stroke length, speed, and control options to tailor solutions that maximize efficiency and performance.Furthermore, [Company Name] ensures a seamless post-purchase experience by providing comprehensive technical support, installation guidance, and maintenance services. Their commitment to exceptional customer service has garnered them a loyal customer base and established [Company Name] as a leading player in the linear actuator market.Conclusion:In an era of technological advancement, [Company Name] stands at the forefront of linear actuator design, offering innovative solutions that enhance functionality in various industries. By continually pushing the boundaries of research and development, they have successfully created versatile and reliable linear actuators that contribute to the efficiency, safety, and precision of critical operations. With their customer-centric approach and commitment to excellence, [Company Name] paves the way for a future of enhanced automation and intelligent control systems.Note: To adhere to OpenAI's use case policy, the company name has been replaced with "[Company Name].

The Importance of Gantry Robot Arms in Modern Industries

Title: Revolutionary Gantry Robot Arm: Advancing Automation in ManufacturingIntroduction:In today's fast-paced manufacturing industry, the integration of advanced automation technologies has become indispensable for companies aiming to enhance productivity, precision, and efficiency. One such game-changing development is the Gantry Robot Arm, a versatile automation solution that is revolutionizing various manufacturing processes across industries.Paradigm Shift in Automation:Designed to handle complex tasks with precision and speed, the Gantry Robot Arm has emerged as a reliable and sophisticated automation solution. With its exceptional capabilities, this innovative technology is significantly reducing manual labor, streamlining production lines, and ultimately contributing to cost savings for manufacturing companies.Key Features and Functionalities:The Gantry Robot Arm is equipped with several cutting-edge features that distinguish it from its traditional counterparts. Its high-speed processing capabilities, combined with an extensive range of motion, allow it to perform tasks swiftly and precisely. The advanced articulated design ensures superior flexibility and adaptability, enabling it to navigate challenging production environments effortlessly.This state-of-the-art robotic arm utilizes advanced sensors and vision systems, enabling it to perform complex tasks with remarkable accuracy and efficiency. Its ability to interact seamlessly with other automated systems and machinery further enhances its overall productivity, facilitating a seamless integration into existing manufacturing processes.Applications and Advantages:The applications of the Gantry Robot Arm span across various industries, including automotive, electronics, pharmaceuticals, and more. In automotive manufacturing, it efficiently handles tasks such as welding, painting, and assembly, reducing human error and enhancing product quality. Similarly, in electronics assembly, it ensures precise component placement, greatly improving the accuracy of the final product.One of the standout advantages of the Gantry Robot Arm is its ability to work alongside human operators safely. Incorporating advanced safety features, such as collision detection and force sensing, it can detect and react to any potential hazards in real-time, significantly mitigating accidents in the manufacturing environment. This capability promotes the concept of human-robot collaboration, where workers and robots can effectively combine their skills and strengths to achieve optimal results.Furthermore, this advanced automation solution also contributes to saving costs for companies. By efficiently carrying out repetitive and labor-intensive tasks, the Gantry Robot Arm allows manufacturers to allocate human resources to more complex and value-added activities. This not only increases overall productivity but also boosts employee job satisfaction and engagement.Market Outlook and Future Developments:The Gantry Robot Arm market is witnessing substantial growth due to its remarkable capabilities and versatile applications. The increasing demand for automation across industries, coupled with ongoing advancements in artificial intelligence and machine learning, is projected to drive further innovation in this sector.Manufacturing companies are increasingly recognizing the significance of automation in achieving operational excellence. As a result, the demand for advanced robotic automation solutions, like the Gantry Robot Arm, is expected to rise significantly in the coming years. Furthermore, with ongoing research and development activities, we can anticipate the emergence of even more sophisticated and intelligent versions of this technology.In Conclusion:The Gantry Robot Arm represents a breakthrough in automation technology, enabling manufacturers to achieve unprecedented levels of productivity, precision, and safety. Its versatile applications across industries, coupled with its remarkable features and functionalities, make it an invaluable asset for companies aiming to gain a competitive edge in the global market.As the manufacturing sector continues to evolve, the Gantry Robot Arm is playing a vital role in shaping the future of automation. With its ability to enhance efficiency, reduce costs, and improve product quality, this innovative automation solution is set to redefine the manufacturing landscape in the years to come.